Avoid Failures: Smart Erection and Maintenance of Aeration Blowers in STP/ETP Systems

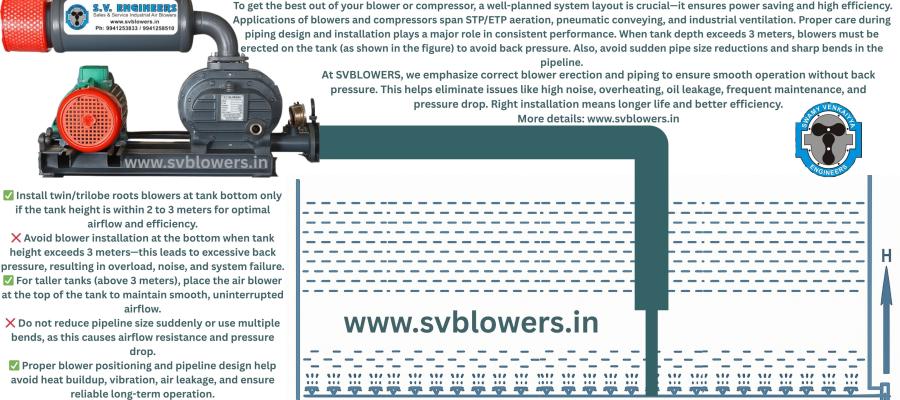

Proper erection and maintenance of twin lobe roots air blowers are crucial for efficient aeration in STP and ETP plants & other applications. For tanks above 3 meters, blowers should be installed on top to prevent back pressure, noise, and overheating. Avoid sudden pipe size reductions and sharp bends in piping layout. Regular maintenance and correct installation ensure long-term performance, reduced service issues, and energy savings. Trust SVBLOWERS for reliable blower solutions.

More info: www.svblowers.in

How to Properly Erect and Maintain Twin Lobe Roots Air Blowers in STP & ETP Aeration Applications –

you tube video link : https://youtu.be/drE09uKqvr0

Avoiding Back Pressure & High Temperature Failures At S.V. Engineers, we have over 20 years of experience with sales and service of 7000+ units of Twin Lobe and Tri-Lobe Roots Air Blowers used across a wide range of applications—STP & ETP aeration, aquaculture hatcheries, cement bulker unloading, biogas plants, and raw material conveying systems. One of the most common issues in STP & ETP aeration blowers is excessive back pressure, which leads to overheating and rapid blower failure. Based on our extensive field experience and technical service records, we’ve found that many blowers start facing problems when discharge pressure exceeds 0.4 kg/cm², especially when the blower models are rated for a maximum of 0.7 kg/cm² (some even only up to 0.4 kg/cm²). Common Back Pressure & Overheating Issues in Roots Blowers:

1. Rising Temperature: Excessive back pressure raises the blower casing and oil temperature. 2. Lubricant Breakdown: High heat reduces oil viscosity, leading to oil thinning, leakage, and seal failure. 3. Oil Seal & Gear Damage: Low-viscosity oil fails to protect internal parts—causing wear of gears, bearings, and shafts. 4. Frequent Spare Replacements: Without corrective action, clients end up replacing oil seals, shafts, and bearings frequently, incurring high maintenance costs. 5. Blaming Brands or Service Teams: Even after switching brands or service teams, the problem persists if erection and operation mistakes aren't corrected.

✅ Do's for Proper Erection of Roots Blowers: Proper Erection of Roots Type Blowers – Checklist To ensure safe, reliable, and efficient performance of twin/triple lobe Roots air blowers, follow the below erection steps: 1. Free Rotation Check Before coupling the motor, manually rotate the blower shaft to ensure smooth, free rotation without any internal obstruction or abnormal resistance. 2. Confirm Motor Rotation Direction Verify the motor’s rotation direction matches the blower's specified direction (usually marked with an arrow on the blower body). Wrong rotation can cause back pressure and damage internal components.3. Gear Oil Lubrication Level Fill the blower gearbox with the recommended grade of gear oil (usually SAE 90 or 140). Ensure the oil level is maintained between the MIN and MAX marks on the sight glass or dipstick. 4. Pulley & Belt Alignment Ensure proper alignment between the motor and blower pulleys. Use a straight edge to check parallelism. Tension the V-belts correctly — neither too tight nor too loose — to avoid belt wear and slippage. 5. Delivery Line Valve & NRV Check All delivery pipelines must be clear and the discharge isolation valve and non-return valve (NRV) should be fully open during blower operation to avoid back pressure and motor overload. 6. Strong Base Foundation Mount the blower and motor on a rigid, vibration-free base frame or RCC foundation. Use anti-vibration pads if required. Ensure proper levelling and secure with foundation bolts. 7. Suction Silencer & Air Filter Fitting Properly install the suction silencer and air filter on the blower inlet to prevent dust or particles from entering. Use flexible connectors to reduce vibration transmission to piping.

✔ Install a non-return valve (NRV) on the pipeline to avoid reverse air flow and protect the blower during shutdown. ✔ Ensure pipe diameter matches or is larger than the blower outlet to reduce back pressure. ✔ Provide an open or properly vented discharge point to release air without resistance. ✔ Always install pressure relief valve (PRV) calibrated slightly below the max blower pressure rating. ✔ Use high-quality gear oil & Grease (temp range 40°C–120°C) and maintain oil level & putting grease as per manufacturer’s spec. ✔ Keep air filters clean and replace them periodically to avoid suction blockage.

❌ Don’ts in Roots Blower Erection & Operation: ❌ Don’t Erection Bottom of the tank Level. ❌ Don’t use more bend pipe line & don’t take bends nearby of the air blowers. ❌ Don’t use low-quality or wrong-grade lubricant. Gear oil & grease ❌ Don’t reduce pipe size after blower discharge—it increases pressure and heat. ❌ Don’t operate continue the air blowers above their rated pressure & temperature. ❌ Don’t block or restrict air discharge—causes back pressure immediately. ❌ Don’t install blower in a poorly ventilated or hot room—air-cooled units need ambient airflow

❌ 1. Do Not Install the Blower Below Tank Level Always install the blower above or at the top level of the tank. Installing below tank level can cause: Backpressure issues / temperature increase / Increased vibration and noise / Frequent oil leakage / Higher maintenance / Shorter blower life

❌ 2. Do Not Reduce Pipe Size or Use Excess Bends Use only the manufacturer-recommended pipe size. Avoid: Reducing pipeline diameter / Excessive pipe bends / Blowers from upward Vertical discharge lines above 2 meters / Mismatched header connections � � When using two blowers into a common header, the header pipe must be double the size of a single blower outlet. After the header, maintain the same size as the blower delivery. � � Recommended pipe material: MS / SS for outside lines, and PVC/UPVC only for sections inside water tanks.

❌ 3. Never Run the Blower Without Lubrication Running even for a minute without proper gear oil will damage internal parts. Always fill oil to the recommended level before starting.

❌ 4. Do Not Run the Blower in Reverse Rotation Avoid using motors with: Ensure the motor runs in the correct direction as marked. Reverse rotation causes internal damage and loss of performance.

❌ 5. Do Not Use Incorrect Motor HP or Speed Lower or higher RPM than recommended / Lower horsepower than required � � Incorrect motors lead to overloading, underperformance, and early failure.

❌ 6. Never Operate with Delivery Valve Closed Always ensure that the blower outlet valve is open before starting. Running with the valve closed builds extreme pressure and risks damage to the blower, pipe, and motor.

❌ 7. Do Not Service While Running Never attempt to: Fix or remove any parts / Replace oil or filters / while the blower is in operation. � � Always switch off, isolate power, and let the blower cool before servicing.

❌ 8. Don’t Disassemble the Blower Yourself Avoid self-disassembly to prevent: Damage to cast iron casing Improper handling of internal clearances � � in case of breakdown, contact SVBLOWERS service engineers or send the blower to a service center equipped with proper tools and expertise.

https://www.svblowers.in / [email protected]

� � Solutions to Avoid High Temperature in Roots Blowers: ✅ Install pressure gauges at both inlet and outlet to monitor real-time pressure. ✅ Ensure proper ventilation for all the air blowers. ✅ PROPER ERECTION ON THE TANK Roots air blower systems, continuous operation of a single blower can cause overheating and early wear. To avoid this, a temperature-based and timer-based control system can be used to alternate blowers efficiently. 1. Timer/PLC Controller: Set to operate blower A for a fixed time (e.g., 1,2,4,8 hours), then switch to blower B. set time temperature rises time based 2. Auto Changeover: When: o Blower A exceeds present temperature (e.g., 50°C), OR o Timer expires (set runtime), o The system automatically starts Blower B and stops Blower A. 3. Rest Time: Gives rest period to the first blower, avoiding thermal stress and extending its life. Currently, Blower A is running. When the surface temperature of Blower A rises above 50°C, it becomes too hot to touch, indicating it needs a break. Whether it happens after 1 hour, 2 hours, 4 hours, 8 hours, or even just 30 minutes — once that threshold temperature is reached, Blower A will automatically or manually shut down to rest. At that point, Standby Blower B will start and take over the operation. While Blower B runs, Blower A gets time to cool down. This process continues in a loop — once Blower B reaches the same temperature limit, it shuts down, and Blower A starts again.

� � Best Practices in Maintenance of Twin Lobe Roots Blowers: ✅ Daily check for unusual noise, vibration, or oil levels. ✅ Weekly inspection of air filter cleanliness and foundation bolts. ✅ Monthly servicing: Lubricant check, temperature logging, belt tension. ✅ Quarterly check-up: Pressure drop analysis and minor part inspection. ✅ Annual service: Overhaul if necessary—oil seals, bearings, and gear inspection. ❓ Why Are Positive Displacement Blowers Used in Most STP, ETP & Aquaculture Aeration Applications? Positive displacement (PD) blowers, like twin and tri-lobe roots blowers, are ideal for working-pressure (0.1–1 kg/cm²) continuous air delivery in STP, ETP, and aquaculture. They offer: Air cooled blowers working pressure (0.1–7 kg/cm²) depending of model it will change Water cooled blowers working pressure (0.1–1 kg/cm²) depending of model it will change All blowers without problem working pressure (0.1–3 kg/cm²) noise, oil leakage, heat, Constant volume output regardless of system pressure. Robust performance for continuous operation. Hours depending of the plant designing. Simple design, easy service, and long operational life. This makes PD blowers the most preferred type in aeration systems where consistent airflow and durability are critical. This type of twin lobe / try lobe roots air blower is used to provide air to these types of microorganisms in the aeration tank & mixed sludge in sewage water treatment plants & effluent water treatment plants. When the air blower is used at moderate pressure, the microorganisms grow very well (below 0.1kg/cm2 to 0.3kg/cm2) without back pressure, but ( more than 0.4 kg/cm3 ) when the pressure is increased, the heat increases and the hot air travels at high pressure and attacks the microorganisms, causing the affected microorganisms to die or not grow. The tolerance of these types of microorganisms, i.e. pressure and heat, is very low. Why Use Twin-Lobe Roots Air Blowers for STP / ETP / SHRIMP HATCHERY Aeration? Twin-lobe Roots air blowers play a vital role in the efficient functioning of Sewage Treatment Plants (STP) and Effluent Treatment Plants (ETP), Aquaculture (shrimp hatchery) particularly in the aeration process. Their robust and reliable operation ensures that the biological treatment processes receive the necessary oxygen for microbial activity.

Key Benefits in STP/ETP Aeration: 1. Consistent Airflow Delivery Twin-lobe Roots blowers are known for delivering a steady, pulse-free air supply, ensuring uniform oxygen transfer in aeration tanks. This is essential for the effective breakdown of organic waste by aerobic bacteria. 2. Pressure Stability These blowers maintain constant flow rates even during system pressure fluctuations, helping to avoid oxygen level drop in the aeration tank. 3. Energy Efficiency Engineered for low energy consumption, they help reduce electricity usage, contributing to the overall cost-effectiveness of the plant. 4. Low Maintenance Their simple design with fewer moving parts results in minimal wear and tear, reducing downtime and maintenance costs. 5. Reliable Operation Suitable for continuous operation with standby blower, twin-lobe Roots blowers ensure long-term reliability in wastewater environments& others applications. 6. Customizable and Scalable Available in various sizes and capacities, they can be tailored to meet plant-specific oxygen demands. Additional Applications of Twin-Lobe Roots Blowers: Apart from STP/ETP aeration, these blowers are widely used in multiple industries due to their versatile performance: Aquaculture Aeration: Maintaining dissolved oxygen levels in fish and shrimp ponds. Cement & Fly Ash Handling: Pneumatic conveying of powdered materials. Sugar Industry: Molasses aeration and vacuum filtration systems. Paper & Pulp Industry: Wastewater treatment and pulp agitation. Chemical Plants: Gas transfer and oxidation processes. Food Processing: Fermentation and air agitation. Electroplating: Tank aeration for uniform plating results. Conclusion Twin-lobe Roots air blowers are an ideal choice for STP/ETP aeration applications due to their robust design, efficient performance, and low operating costs. Their versatility also makes them suitable for a wide range of industrial air applications, making them a valuable investment for any facility that requires reliable and efficient air movement. Contact us at S.V. Engineers for complete support on blower selection, site erection guidance, and annual maintenance programs across Chennai, Coimbatore, Bengaluru, Hyderabad, Kochi, and all major South Indian cities.

aeration blower efficiency aeration blower erection guide aeration blower maintenance Aerzen India blower blower back pressure issues blower back pressure solution blower erection best practices blower noise and heat issues blower noise reduction blower piping design etp aeration blower setup etp plant blower erection etp twin lobe blower erection Everest roots blower how to install twin lobe blower how to maintain stp blower how to maintain twin lobe blowers Indian blower brands for STP Indian manufacturers of roots blowers industrial blower maintenance Kay International blower KPT Blower India roots blower maintenance tips roots blower piping layout roots blower troubleshooting Roots India blowers stp aeration blower maintenance India stp blower installation guide stp etp blower installation India stp etp blower piping layout stp etp blower system design SVBLOWERS installation and service svblowers installation guide svblowers stp solutions svblowers twin lobe blower TNEI blower India twin lobe blower maintenance tips twin lobe blower service twin lobe roots blower erection twin lobe roots blower erection India

Avoid Failures: Smart Erection and Maintenance of Aeration ...

Proper erection and maintenance of twin lobe roots air blowers are crucial for efficient aeration ...

STP & ETP Aeration: Best Practices for Twin ...

This blog explores the best practices for installing and maintaining twin lobe roots blowers used ...

FAQs on Erection and Maintenance of Twin Lobe ...

This FAQ guide answers the most important questions regarding the erection and maintenance of Twin ...